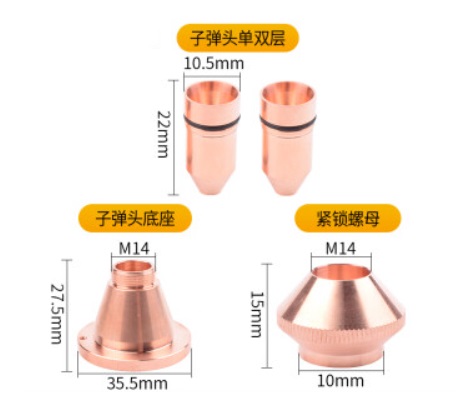

10.5mm Bullet Nozzle Assembly Fiber Laser Cutting Machine Nozzle

-

Send Email

- Product Details:

Payment & Shipping Terms:Place of Origin: China Brand Name: QTC Certification: ISO Minimum Order Quantity: 50 pieces Packaging Details: plastic box Delivery Time: 3-5 days Payment Terms: Western Union, MoneyGram, T/T Supply Ability: 1000 pieces per day Description:

Mob/ Wsap: +86 18652986859 Spare Parts Type: Laser Spare Parts Used For: Fiber Laser Head Material: T2 Red Copper Layer: Single / Double E Mail: [email protected] High Light: 10.5mm Bullet Nozzle

,10.5mm Bullet Nozzle Assembly

,fiber laser cutting machine nozzle

Laser nozzle is a small part of the laser cutting machine, but it plays a very important role, the laser nozzle will have a great impact on the laser beam, the nozzle size allows only the beam through, can effectively avoid the work of possible problems.

Product name Bullet nozzle Laser Cutting For Fiber Laser Head Machine Laser Brand Raytools/WSX/Precitec/HANS,ect Application Laser Machine,Laser Cutting Machine,Metal Machine Material Red Copper T2 10.5mm Bullet Nozzle Assembly Fiber Laser Cutting Machine Nozzle

General laser cutting nozzles are divided into single and double layers.

Single-layer nozzles are used for melting and cutting, nitrogen is used as auxiliary gas, it is used to cut stainless steel, aluminum alloy, brass, etc.

Double-layer nozzles are generally used for oxidative cutting, using oxygen as an auxiliary gas, usually used for cutting carbon steel.Single-layer: Melt cutting; Nitrogen; Stainless steel, Aluminum 1. 4-3.0mm

Double layer: Oxidative cutting; Oxygen; Carbon steel;1.5-3.0mm

In the laser cutting process, the main factors that affect the cutting quality performance include laser beam quality, laser power, cutting speed, workpiece thickness, material type, etc. In addition, the nozzle design of the laser cutting head is also an important factor.

The nozzle is usually installed at the front end of the laser cutting head, which helps to control the auxiliary gas and protect the focus lens.

On the one hand, when the nozzle center is different from the laser center, it will cause the following effects:

1.When the cutting gas is sprayed, the gas volume is not uniform, so the cut part is more likely to have one side that is melted, and the other side does not have a side that is melted. In particular, when the thickness of the cut metal plate exceeds 3 mm, the effect is more serious, and sometimes it cannot be cut.

2.When cutting workpieces with sharp or small angles, local excessive melting may occur, which affects the cutting quality. It may also make it impossible to cut thick plates.

3.Especially when perforating a thick plate, it will cause instability in the perforation process, time is not easy to control, and the penetration of the thick plate may lead to excessive melting.

Nanjing RTS laser technology co., LTD. (hereinafter referred to as RTS laser) is a high-tech enterprise which has a innovative and professional technical team in the fiber laser field, our members who formerly worked for famous laser enterprises both at home and abroad have decades of work experience and a wealth of experience of on-site troubleshooting with reasonable price and short maintenance cycle. In addition, RTS laser has set up a research center, which makes us a supplier who integrates the development R&D, production and service of materials, device integration and laser source related products such as optical fiber.

Recent Products

- Product Details:

Leave a comment